Modern stormwater management requires more than just pipes and catch basins. Increasing rainfall intensity, urban development, and environmental regulations demand systems that can store and release storm water safely. Precast concrete vaults and chambers have become the backbone of stormwater storage, offering cost effectiveness, long term durability, and structural integrity for projects across the United States.

Why Stormwater Storage Matters

When surface water runs off rooftops, parking lots, and streets, it must be captured and controlled. Without proper stormwater storage, drainage systems can overload, leading to flood damage, erosion, or contamination of waterways. Stormwater management structures are designed to collect storm water, hold it temporarily, and release it through an outlet pipe into a storm sewer or natural channel.

Precast concrete vaults and chambers handle this process efficiently. Unlike a french drain, which slowly infiltrates water into the soil, these engineered structures provide predictable performance even when dealing with large amounts of stormwater runoff.

The Role of Precast Concrete

Precast concrete storage systems are manufactured in a controlled environment using proven manufacturing processes. This ensures every unit meets strict PennDOT standards such as PennDOT class A concrete, PennDOT concrete mix designs, and PennDOT concrete certification. Products listed under PennDOT Bulletin 15 approved products and construction materials are approved for use in public infrastructure.

In addition, suppliers that are NPCA certified or operate an NPCA certified plant guarantee consistency and quality control. By working with precast concrete companies in Pennsylvania, contractors gain access to precast products that are tested, durable, and compliant with state and federal standards.

Vaults, Chambers, and System Integration

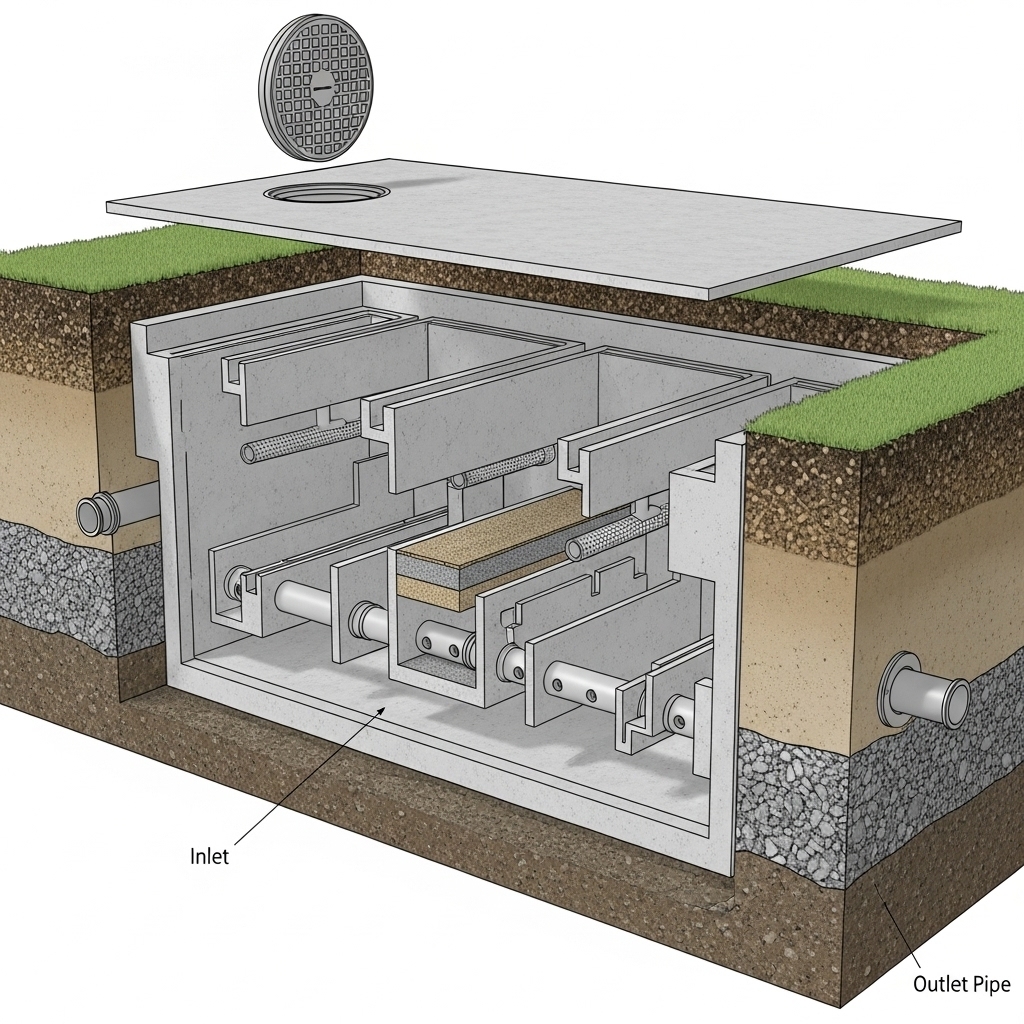

Precast stormwater vaults are large underground structures designed to hold runoff before it enters the stormwater system. Chambers are modular components that create flexible layouts for detention or infiltration. Both options are tied directly into drainage systems, connecting with storm drain box, storm drain basin, or stormwater catch basin assemblies that capture surface water.

For added accessibility, vaults often integrate with manhole precast units or precast concrete manholes to allow inspection and maintenance. These manholes may also be tied into sewer manholes, storm manholes, or sanitary sewer manhole systems. In treatment plant applications, precast vaults manage peak flows before water is directed into sanitary sewer systems for processing.

Structural Principles and Pipe Connections

Stormwater storage depends on proper integration of reinforced concrete pipe (RCP). Selecting the right pipe size and ensuring secure pipe connections is essential to maintaining structural integrity. Outlet pipes control the rate of discharge, while inlet structures like catch basins and grated drains ensure efficient water collecting.

Precast chambers and vaults are designed to collect and release water gradually, protecting downstream channels from erosion. By using high strength mixes and reinforced walls, these systems remain reliable under heavy duty conditions such as roadways and industrial sites.

Precast vs. Cast in Place

While cast-in-place concrete has historically been used for large storage tanks, precast solutions offer clear advantages. Precast concrete production ensures dimensional accuracy, faster installation, and predictable performance. Precast concrete plants manufacture units that can be delivered and installed with minimal site disruption.

For a construction project, precast systems reduce downtime and improve cost effectiveness. Instead of waiting weeks for cast in place concrete to cure, precast units arrive ready for installation, accelerating schedules and reducing labor costs.

Applications Across the Construction Industry

Precast vaults and chambers are applied in a wide range of construction industry projects:

- Parking lots: Manage runoff from impervious surfaces and tie into storm sewer manhole systems.

- Treatment plant facilities: Store and control stormwater before discharge into sanitary sewer manhole or sewer manholes.

- Residential developments: Combine catch basins and small vaults to prevent water damage to homes.

- Highway projects: Use storm drain structures, outlet pipe assemblies, and vaults to manage large volumes of stormwater runoff.

Each construction project benefits from the reduced installation time and reliable service life of precast stormwater storage products.

Service Life and Long Term Value

The service life of precast storage systems is a defining advantage. By resisting chemical attack, freeze-thaw cycles, and soil pressure, precast vaults and chambers deliver decades of performance. When paired with quality concrete manhole covers, outlet structures, and catch basins, they provide a complete drainage solution that minimizes maintenance needs.

For municipalities and engineers, the long term value lies in both reduced maintenance and improved resilience against extreme weather. By controlling the amount of storm water released, these systems protect communities from flooding while extending the lifespan of surrounding infrastructure.

Quality Control in Manufacturing

Every precast storage system undergoes strict quality control. Testing covers compressive strength, reinforcement placement, and dimensional accuracy. Plants that are NPCA certified plants must document every step of the manufacturing process to meet regulatory requirements. This ensures consistency across Pennsylvania and beyond.

By relying on a controlled environment, suppliers eliminate variables that compromise cast-in-place concrete. Contractors receive high quality units that integrate seamlessly into existing networks of catch basins, stormwater systems, and pipe systems.

Conclusion

From underground vaults to modular chambers, precast solutions for stormwater storage provide unmatched efficiency, cost effectiveness, and long term performance. Manufactured in a controlled environment, they deliver high strength and structural integrity while meeting PennDOT and NPCA requirements.

For any construction project, whether a parking lot, treatment plant, or highway system, precast stormwater storage systems are the reliable choice. By integrating with catch basins, outlet pipe assemblies, and manholes, these products ensure stormwater runoff is safely managed and released into larger stormwater management systems.

With consistent precast concrete production, rigorous quality control, and proven service life, precast vaults and chambers remain the foundation of modern stormwater infrastructure.