When designing reliable drainage systems, understanding how to properly build manholes and inlet structures is critical. From the base section to the manhole cone and final surface fittings, every component plays a role in managing flow, preventing standing water, and protecting communities. At Eagle Concrete, we provide precast concrete manholes, precast catch basins, and grated inlets engineered to meet the highest standards, including certification as PennDOT Bulletin 15 approved suppliers.

Starting with the Base

Every sanitary manhole or storm sewer manhole begins with a durable reinforced concrete base. These bases are designed with openings sized to fit the right pipe size, allowing precise pipe connections for storm sewer, outlet pipes, or sewer systems. Pre-engineered bases reduce on-site labor and ensure long-term performance.

For catch basins, the base acts as the first line of defense in controlling surface runoff. Whether it’s a concrete catch basin for a roadway or a precast concrete catch basin in a commercial site, these structures are designed to collect excess water and direct it underground.

Riser Sections and Adjustments

Above the base, concrete manhole risers or a catch basin riser are stacked to bring the structure to grade. Catch basin precast risers allow for flexibility in depth, making them an efficient construction material for various jobsite conditions.

Grade adjustment rings further fine-tune the elevation, ensuring that the final curb inlet frame and grate or storm drain cover sits flush with the pavement. Proper elevation is critical in parking lots and streets where heavy traffic and pedestrian access are factors.

The Manhole Cone and Top Section

The manhole cone narrows the riser to the correct opening size for a storm drain cover, storm drain covers, or inlet grate. Depending on design needs, cones may be eccentric or concentric. Eagle provides heavy-duty concrete storm drain tops that work seamlessly with ductile iron covers, ensuring durability under high loads.

For sanitary systems, watertightness is essential. That’s why bituminous coating and bituminous waterproofing are applied to concrete manholes and sanitary manholes. These coatings extend service life by protecting against corrosion and infiltration.

Grated Inlets and Catch Basins

Inlet structures vary depending on application:

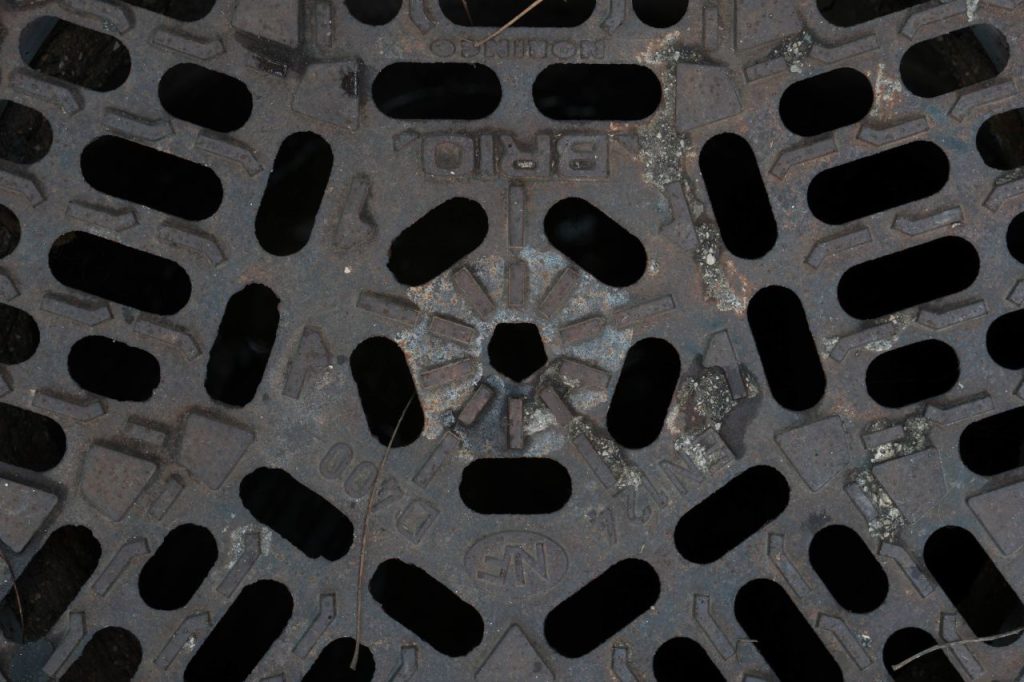

- Grated inlets use an inlet grate to allow water entry while blocking debris from entering the system.

- Curb inlets designs are common along streets, where runoff flows directly from the curb line. Curb inlet protection measures, like filters or barriers, help prevent sediment from clogging the system.

- Concrete catch basins are used to intercept and direct water flow. Catch basin grates and catch basin for drainage units are sized to handle large volumes of runoff.

Modern designs often require bicycle safe and ADA compliant grates to ensure safety for pedestrians and cyclists. Eagle provides solutions that meet these requirements while maintaining flow efficiency.

Covers, Grates, and Load Ratings

Selecting the right storm drain grate, storm drain cover, or catch basin grates depends on application. In high-traffic areas, heavy duty ductile iron grates are required. In residential or light-duty environments, lighter options may be used.

Galvanized anchor bolts secure frames and grates, preventing shifting under load. By combining strong tops with well-engineered access points, contractors ensure long-term performance of both sanitary sewer manholes and storm structures.

Applications Across Drainage Systems

Manholes and inlets are critical in:

- Parking lots, where proper drainage prevents puddling and property damage.

- Storm drains for urban roads, ensuring runoff is quickly diverted.

- Sanitary systems, where sanitary manholes provide inspection points for sewer lines.

- Treatment plants, where storm manholes and sanitary structures tie into larger facilities.

Each installation requires attention to pipe connection, outlet pipes, and the right combination of precast concrete manholes, precast catch basins, and grates.

Why Precast Is the Standard

Choosing precast concrete products ensures consistency, compliance, and efficiency. Unlike cast-in-place options, precast concrete manholes and precast concrete catch basins are manufactured in controlled environments, guaranteeing quality. This reduces jobsite labor and minimizes risks of failure.

Eagle Concrete lead the industry by offering precast manholes, catch basins, and storm drain grates designed to withstand heavy use. With certifications as PennDOT Bulletin 15 approved suppliers, we provide peace of mind for municipalities and contractors that every component will meet regulatory standards.

Conclusion

Building a manhole or inlet structure requires careful planning from base to grate. The right combination of reinforced concrete, riser sections, manhole cone, and properly selected storm drain covers or grated inlets ensures durability, efficiency, and compliance. Add in protective measures like bituminous coating and bituminous waterproofing, and these structures can deliver decades of reliable service.

At Eagle Concrete, we don’t just provide catch basins and concrete manholes—we deliver solutions that simplify installation, protect communities from excess water, and ensure every drainage system is built to last. From curb inlet frames and grates to stormwater catch basins, our products are engineered to help contractors build with confidence.